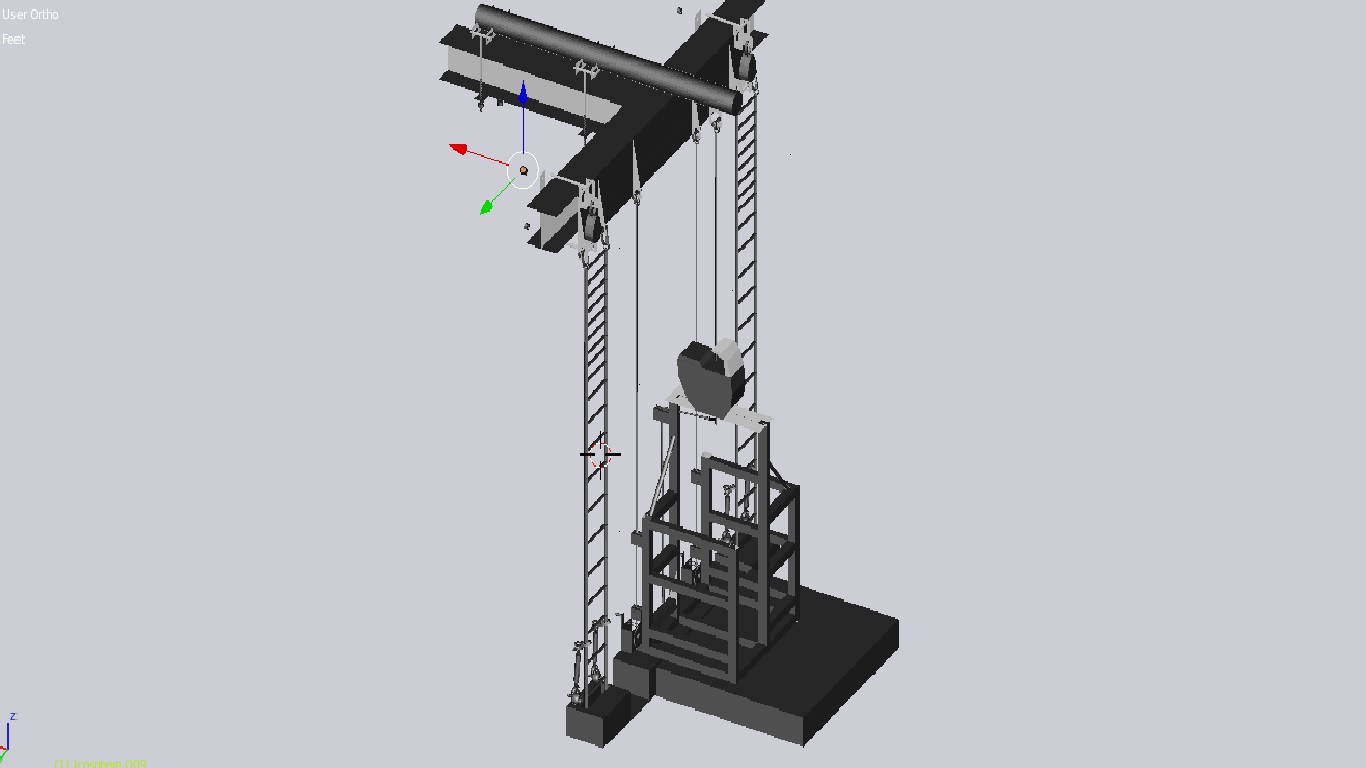

The C.A.L.

The Caged Access Lift (CAL) System is one of the safest, most efficient access systems. It is best suited for high point access areas in refineries, manufacturing and chemical plants, and commercial construction or restoration. The CAL can provide a safe way to access high point areas which may be difficult to access. The CAL is versatile to accommodate almost any access point desired. It is a system which is compact, easy-to-use and assemble . The CAL also provides a perhaps safer alternative to accessing high points which may require climbing ladders, scaffolding or long staircases. The CAL is economical considering the costs involving extended labor hours for scaffold construction and dismantling, OSHA citations, and above all worker injury.

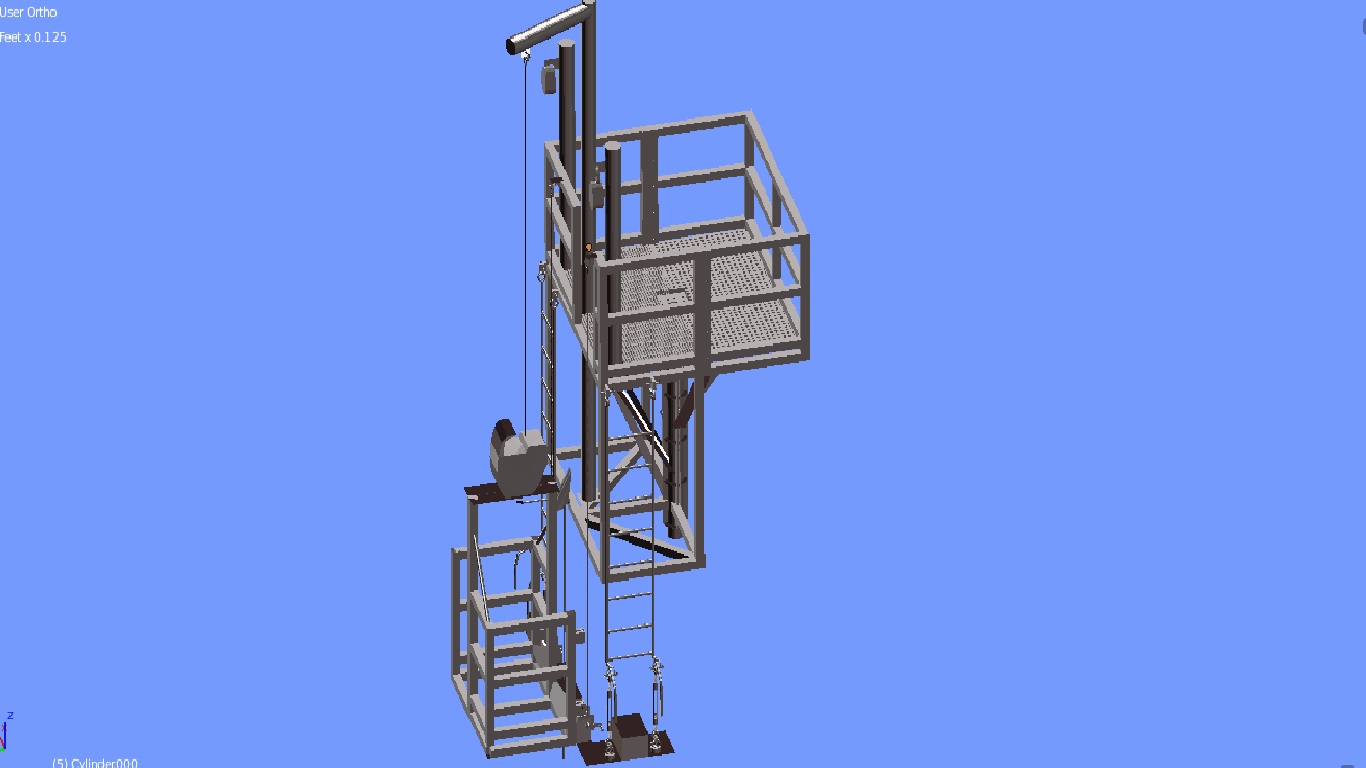

The C.A.P.S.

The Coil Access Platform System (CAPS), is one of the safest and most efficient access platform systems available to provide access to injectors for maintenance and performing offshore coil tubing downhole operations. CAPS is a complete stand-alone system is shipped ready for installation with minor assembly requirements. CAPS, in most ways, is more economical , safer, and generally a much better solution than using scaffolding, ladders or other conventional high point access systems. CAPS uses a small footprint for operation; therefore it significantly removes the dangers maneuvering around large temporary structures and provides a clear work area minimizing tripping hazards.

The key to C.A.P.S. LLC., products is SAFETY!!!! We engineer, manufacture and service our products with the main goal of keeping all users of our products safe and hazard free. The added bonus of using the CAL or CAPS system is costs savings!!!! Comparable systems such as scaffolding are time consuming and inflate job costs due to excessive labor hours. The CAL and CAPS systems both save time and money!!!!

Some other advantages to using the CAL or CAPS system are both systems provide accommodation for compliance to dropped objects and safety gate failure prevention plans. A "no gaps" safety gate with a canvas mesh, secured with a double D ring nylon strap, extends from the guardrail to the toe plate and makes it very difficult for any object to fall from the lift cage floor. CAPS and CAL systems also employ a patented; engineer approved slotted, bolt and nut system which do not require the use of hand tools to complete assembly. All the bolt and nut systems are self-contained and require hand tightening only. These components are tethered to the equipment with an engineer approved connection process also eliminating the risk of these components to be "dropped objects". The safety gate is constructed from the same 3” x 3” heavy gauge aluminum tubing as our platforms. The gate and its adjacent guardrail post join at a 45 degree angle to eliminate any openings between the gate and the guardrail. Due to this “no gaps” engineered latching system that incorporates failure prevention, there is also very little chance of injury.

C.A.P.S. LLC., is an ISO 9001 compliant company. All components and materials used in the manufacturing and production of all C.A.P.S. LLC., products are made in the United States of America and in compliance to ISO 9001 standards. All fabricators used in the manufacturing of all C.A.P.S. LLC., are also ISO 9001 certified or compliant.

We look forward to the opportunity to serve you!!! Please contact us to find out more about these revolutionary products!!! Start saving money and making your work environment safer today!!!!